What is SPANDEX? How it was developed?

Spandex is the general name of synthetic polymers (acrylics) that have a perfect elongation property and can take their old shape again when the strain is eliminated. They are also called as polyurethane elastomer fibers. In addition, lycra (lycra) is the trade name of spandex (elastane) fiber. Fiber varieties with high elongation ability are classified as elastomer (elastic) fibers. These fibers show a very high elongation rate (400-800%) without breaking and can quickly return to their former state in the elongations up to the breaking point.

Spandex was found by Bayer in 1937 and has made strides in many areas with its harsh form. In 1941, it was seen that it was a fiber that could be given a tire-like feature and in 1967 it was sold in Japan for the first time under the name of Mobilon in its final form. In 1977, it was continued by Kanebo under the Lubell brand name and the name was changed to Spantel. It is called spandex by the USA because it is chemically polyurethane-based fibers.

Spandex fibers are materials produced in the form of segmented polyurethane fibers, 85% of which are composed of long-chain synthetic polymers by weight. It was invented by chemists C.L. Sandquist and Joseph Shivers. Lycra yarns, in the simplest sense, are yarns consisting of synthetic (polymer) lycra fibers (acrylic) in the form of filaments.

What are the uses of spandex? In which products is Spandex used?

Spandex / Lycra, which has a very common use, is of great importance today. Spandex fiber is used in products; It adds unique features such as comfort, harmony to the body and freedom of movement.

Today, the use of elastomer fibers has spread over a wide area and products from the mixture of cotton, viscose, polyester, polyamide fibers and elastomer fibers are in our daily use. Spandex yarns are preferred in all types of clothing where flexibility is demanded, knitwear, underwear, belts, swimming, skiing, golf, tennis, yoga, plates.

The usage areas of Spandex in Baby Diapers and Adults Diapers

In addition, the place of use of spandex in diapers is very critical. To offer the baby to move freely even in the diaper, and to prevent leakage from the leg and barrier parts spandex has become among the key components of diapers. There are also many elastene fibres at the waist of the diaper in the panty-type diapers to block leakage.

How is spandex is applied in Adult / Baby Diapers?

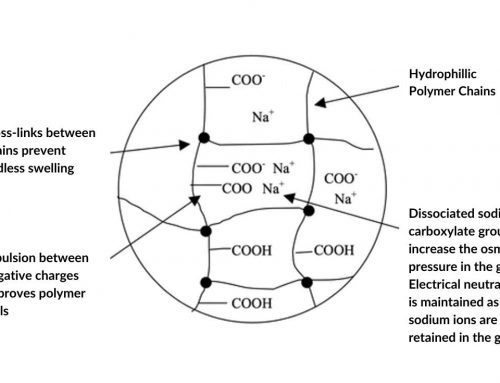

The application of spandex in diaper products is made with glue specially designed for the application of flexible materials. Polybutene-based and non-PSA (pressure sensitive adhesive) adhesives such as polyamide have a number of benefits: It resists to baby oils and lotion, while styrene block copolymers (SBC) based adhesives are commonly used rubber adhesives. SBC-based glues; with relatively short open time being more sensitive to pressure and providing advantages such as low cost and effectiveness. Like construction glues, rubber glues need low surface tension and excellent spiral sprayability. They adhere wet non-polar surfaces well, but in addition, they need high cohesive strength to hold stretched rubber strips.

Hot melt glues used to adhere spandex to baby diaper nonwovens.

What are the Physical Characteristics of Spandex?

The main physical characteristics of Spandex yarns are listed below:

- Their density varies according to their mode of production. What we call production methods are wet and dry shooting and melt shooting types. Their density is lower than polyester and wool.

- As a length; they can be produced from infinite filaments. Depending on where they will be used, they can also be made into what we call a dashed, that is, a staple. Its thinness are produced from 11 dtex (10 denier) to 2600 dtex (2340 DENIER) according to production sectors and needs in the world. They have a good resilience, that is, springing.

- Dehumidification rates are low (0.2-0.8%). Because they are hydrophobic.

- In terms of physical properties, the cross section of acrylic fibers such as spandex, which is produced by dry spinning, is round or bean-shaped and has a high resilience (springing) ability. Those whose cross section is peanut-shaped have good softness and brightness of acrylic fibers. The longitudinal appearance of acrylic fibers is smooth. They are usually produced in white.

- It has good resistance to friction.

- The elongation rate varies between 20-36%. Acrylic fiber can stretch 95% when extended by 1%.

- It is resistant to other acids except nitric acid.

- Its resistance to sunlight is good.

- Bacteria, fungi, mold, moths and other harmfulinsects do not damage the fibers.

- Its electrical conduction is low because it attracts little moisture. For this reason, the problem of static electricity is encountered.

- There is no specific melting point. The melting point is around 220-255 ̊C.

- Resistant to UV light.

- When they encounter flames, they melt by pulling. It leaves a chemical smell and a black soot. The ash is cream-colored, bead-shaped and hard.

How We Can Qualify Spandex Yarns?

Quality managers generally check the below properties of spandex:

- Denier Value of Spandex

- Tensile properties

- Recovery properties

- Draft ability properties

1. Denier / Dtex Values of Spandex

What is Denier System (DEN, DENIER)?

DENIER is the weight in grams of 9000 meters long material, which is used in the numbering of infinitely long yarns and fibers such as silk and filaments. It is also called tier or denier. The general formula of the Denier numbering system is as follows:

DENIER(Td) = Yarn Weight (g) / Yarn length(m)*9000

As the denier grows, the thread thickens. The weight of the one with the largest number of two threads of the same length is also large. So the number is accurate by weight, the length is proportional to the test.

9000 meters of 1 denier of yarn is 1 gram. 9000 meters of 2 denier yarn is 2 grams.

What is Decitex System (DTEX)?

Dtex; is a measure of thickness of a textile yarn and is defined as the weight value in grams of 10,000 meters of textile material (tire/yarn). It is a direct numbering system. In this system, the SI (System International) unit system is used. Weight is expressed in grams and length in meters.

Elastane fibers have round or square cross sections. The linear density can range from 20 to 6000 dtex depending on the application where fibers are required.

Dtex= Yarn Weight (g) / Yarn length(m)*10000

10,000 meters of 1 dtex yarn is 1 gram.10,000 meters of 2 dtex yarns is 2 grams.

1 denier (9000 m) yarn is 1.111 dtex.

Example;

490 DENIER = 540 Dtex

560 DENIER = 622 Dtex

620 DENIER = 688 Dtex

720 DENIER = 800 Dtex

840 DENIER = 933 Dtex

Spandex of different thicknesses are used in different applications. So for example; in heavy cotton fabrics (200 g and above) 78 dtex (70 denier) and 158 dtex (140 denier); or in light fabrics, 22 dtex (20 denier) and 44 dtex (40 denier). After the use of Spandex yarns, various test methods have been developed to examine the condition in fabrics. First of all, the properties of the yarns used should be known (such as strength, neps, hairiness), pot measurement, sanfor (pull) test, rupture test, weight test, tear test. In addition, tests such as elongation, tension and leakage should be performed for spandex used in diapers.

2. Tensile Properties

Tensile properties cover the following test parameters.

- Elongation

- Tenacity

Now, lets see these tensile properties one by one:

a. Elongation

Elongation is the elongation or extension of a substance. The elongation rate is the ratio between the length of the elongation of a substance after where the substance returns on its own and the initial length of the substance. For example, if the elongation rate of a substance is 100%, it means that the substance has doubled since it returned on its own. The elongation rate usually gives information about the elasticity of a substance and is used when comparing the elasticity of various substances. Elongation also indicates the resistance of a substance to high stress states. The tension of the tires used in diapers should not be so little as to cause leakage in the baby’s leg area, nor should it be so much that the baby’s leg will squeeze and cause redness/irritation there. Therefore, the tension of the tires used in diapers is very critical in determining the performance of the diaper.

b. Tenacity

Tenacity is the test property which measures the relative strength of the yarn. Ratio of breaking force to yarn linear density is denoted as tenacity.

3. Recovery Properties

A good spandex should recover close to its original length once after stretching and releasing the applied load. Specific test method is used to test the elongation recovery after stretching the yarn up to 300% elongation. Minimum of 90% recovery in this test qualifies a spandex for textile application.

4. Draft ability properties

Draft ability properties are tested under dynamic condition. Specific equipment is designed to vary unwinding and winding speed of spandex with different friction points to test the draft ability.

REFERENCES

Tekstil Liflerinin Polarize Işık Mikrokobu İle Analizi , İstanbul Üniversitesi Adli Tıp Enstitüsü Fen bilimleri Anabilim Dalı , Yüksek Lisans Tezi , 2011

Elastan İplik Kullanımı (Tekstil Dershanesi-Mayıs 2013/Erol Türkan)., https://www.tekstilteknik.com.tr/spandeks-ipliklerin-kullanim-alanlari-ve-ürune-katma-degeri 2021

Filament İplik Üretimi, Miili Eğitim Bakanlığı Tekstil Teknolojisi, 2011

Leave A Comment