What is Super Absorbent Polymer (SAP)? How it was developed?

Superabsorbent polymers are non-toxic polymers that can absorb more than a hundred times their weight very quickly and do not release liquid under pressure. These polymers are used in diapers, adult diapers, feminine hygiene products, absorbent medical clothing, agricultural applications and other industrial applications. With its use in diapers, it increases the fluid holding capacity of the diapers and reduces the use of cellulose, making it possible for the diaper to have a thinner structure.

SAPs were first developed in the United States in 1960. In 1970, the first SAP was launched as “superslurpers” for use in agriculture and horticulture. SAP was first used in diapers in 1982. The most common uses of SAP are in agriculture and diapers.

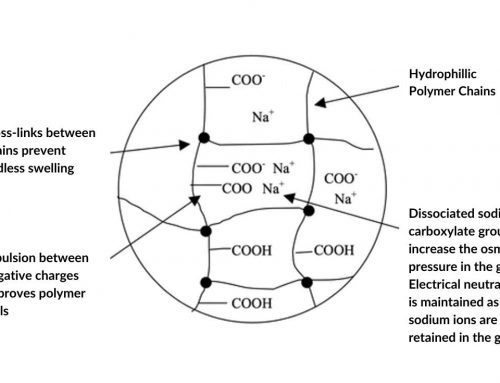

In early applications; The super absorbents are made of chemically modified starch and cellulose, and other polymers such as polyvinyl alcohol (PVA), poly ethylene oxide PEO, all of which are hydrophilic and have a high affinity against water. When chemically or physically cross-linked slightly, these polymers can swell in water but have a water-insoluble structure. Today’s super-absorbent polymers are; It is manufactured from partially neutralized, slightly cross-linked poly (acrylic acid), which has been proven to give the best performance for its cost. Polymers are produced as white solid granules by drying and grinding for both quality and economic reasons. This results in swelling substances such as a rubbery gel that, when wet, can absorb up to 99% water by weight in some cases.

The majority of the SAP content used in diapers is made from sodium polyacrylate and is in granular form or in the form of fibers. The granular material is a polymer consisting of millions of identical sodium acrylates, which are formed into a fence-like structure. These are then connected to each other to make the material into a three-dimensional mesh. When in a dry state, long polymer chains are wound. When they absorb the liquid, they open and the mesh expands. Upon absorption of the liquid, the liquid is then stored in cavities in the molecular network, the superabsorbent swells, and the material forms a hydrogel that traps the liquid. Low-density polymers usually have a higher absorption capacity and swell more. Some types of SAP are also softer and have a higher gelling.

Super Absorbent Polymer

What are the uses of Super Absorbent Polymers? In which products is SAP used?

It is possible to come across super-absorbent polymers in almost every area of our lives. Although these polymers, which can hold high amounts of fluid, are mostly used in diapers, they are also used in many areas from medical applications to agriculture and mining. Someareas of use of PP absorbent polymers:

- Diapers, women’s ties, daily pads, in elderly-sick diapers,

- In operating rooms, absorbent tampons,

- Landscaping, germination, in the production of artificial peat,

- In rooting, seedlings,

- In soil + fertilizer mixtures,

- in keeping the cut flowers in wreaths and bouquets alive for a long time,

- in bandages, in order to absorb blood, in drugs with slow release,

- In coolers, ice containers,

- In petrochemicals,

- In mining,

- Absorption of wastewater, storage of heavy metal ions,

- In places that require waterproofing such as tunnels and pools,

- In fire retardants,

- Water and flame insulation of electricalcables,

- intheabsorption of water and blood in packages of meat and seafood,

- in keeping vegetables moist,

What are the Physical Characteristics of SAP (Super Absorbent Polymer)?

SAPs have hydrophilic (water-loving) properties. When dry, loose and entangled polymer chains move away from each other when they come into contact with the liquid, but complete separation or dissolution does not occur because the chains are connected to each other by cross-links. In this way, it is seen that it can swell and hold hundreds of times as much liquid as their own weight. The amount of liquid that polymers can hold; the structure of the monomers that make up the polymer depends on such properties as the density of the cross-links in the polymer and the electrical charge of the polymer. In addition, the amount of ions of the liquid in contact with the polymer is effective. For example, the SAP can hold 800 times its weight of pure water, while when it comes into contact with tap water, it can hold 300 times its weight. Superabsorbent polymers can absorb up to 50 times its weight in a 0.9% brine mixture.

As SAPs trap the liquid in their bodies, they swell and gel, but they do not release the liquid they trap even under pressure. With these features, their use in diapers is very advantageous.

What are the Benefits and Security Concerns of Using SAP

As a result of extensive tests and researches, the use of SAP in hygiene products has been found to be safe and effective. Doctors and scientists have reviewed the research and confirmed that SAPs are safe.

The safety and benefits of using SAP have been approved by toxicology, general medicine, nursing, and pediatrics. The use of SAP in personal hygiene products has provided great convenience to caregivers and users in terms of health, hygiene, environment and ease of use.

The advantages of using SAP in studies onthe use of SAP in diapers have also been published in numerous studies.

In one study, it was proven that there is a correlation between the use of SAP in diapers and the reduction of diaper rash rate and severity in infants. When the number of clinical trials conducted before and after the use of SAP in diapers is compared, it is reported that diaper-induced diaper rash decreases after SAP use.

In another study, it was stated that the use of SAP in disposable diapers reduced the severity of skin irritation and rash rate seen in infants, and that innovations that were real matched by the engineering approach in diaper design and production significantly reduced the rate of skin irritation and diaper rash. With the innovations in the diaper structure, the first disposable diaper with cellulose content, the first disposable diaper with SAP (1985-1987), the disposable diaper with SAP (1987-1993 and 1993-1996) periods, the disposable diaper with innovations in the design and production of SAP (1987-1993 and 1993-1996) periods are given in the graph below:

In another study, it was stated that the use of SAP in diapers made the baby feel dry and the thickness of the diaper was examined and a more comfortable use was provided, and it was found that this situation provided a serious reduction in the interruption of the babies’ night sleep.

The SAP used in diapers today absorbs urine and traps it in its body and keeps the skin dry by not returning the liquid even under pressure. In the studies carried out, it has been proven that the use of SAP in diapers shows a significant reduction in the wetness of the baby’s skin. In addition, the fact that SAPs absorb and trap the liquid and do not return it even under high pressure ensures that babies do not feel wet even when moving.

Skin PH value has an important role in infant health. The P H value of the mixture of urine and feces in the diaper area is an important factor in the activation of enzymes that damage the epidermal protector. Research has shown that old-type fabric diapers and disposable diapers without SAP cause higher PH value on the baby’s skin surface. On the other hand, the lower P H value of diapers containing SAP was reached. From this, it is concluded that SAPs provide a healthier skin surface by helping to reduce the P H value.

In another study, it was found that high pH and hydration were seen in the areas where diapers were used in babies. In newborn babies, it has been reported that the diapered area gives a pH value of 6.2-6.8, while the leg area outside the diaper has a pH value of 5.2-5.5. This increase in pH causes skin irritation, diaper rash and eczema. If the absorbent product does not leave the skin dry and feel wet, it is stated that it is healthier, that is, low pH values are observed. In addition, it was determined that a big step was taken with the introduction of super-absorbent polymers in diapers and provided high absorbency and healthy skin in this research.

In addition, the biodegradation rate of Super Absorbent Polymer, that is, the reduction of the harmful effect of chemical wastes on the environment as a result of the metabolic activities of microorganisms, is 20%. Such components should not be thrown into nature.

The antibacterial ratio of Super Absorbent Polymer is ≥99. (Ecoli, staphylococcus, candida sporogens)

What are the Important Things When Selecting Super Absorbent Polymers?

Quality managers generally check the below properties of super absorbent polymers:

- Water absorption ability of polymers

- Humidity

- Quality of polymers

- Price of Polymers

Water absorption ability of polymers

The main task of the super absorbent polymer is to absorb water. Therefore, when choosing, attention should be paid to the ability of polymers to absorb water. High levels of this ability will help the polymers absorb water more effectively.

Humidity

The high moisture content of the super absorbent indicates that the polymer has reacted and gives undesirable results regarding the absorption time of the product.

Quality of polymers

The quality of super-absorbent polymers is also very important. Low-quality polymers may have a low ability to absorb water and therefore may not work effectively.

Price of polymers

The area of use of superabsorbent polymers should also be considered when choosing. For example, the properties of polymers to be used in the field of agriculture may be different, and therefore the area of use must also be considered when choosing.

Which test protocols are used when checking the quality of Super Absorbent Polymers?

There are 5 major tests for assessing the quality of Super Absorbent Polymers:

These are:

- Determination of PDS (Particle Size Distribution)

- Determination of Moisture Content

- Determination of Free Swell Capacity

- Determination of Centrifuge Retention Capacity

- Determination of Absorption Under Pressure (AUP)

We can send you the detailed test protocol sheets if you contact us.

If you wonder about Structure of Super Absorbent Polymers and How are They Produced? you can check our blog post below:

REFERENCES

- Akar,E ‘’Aktif Polimerlerin Hazırlanması ve Karakterizasyonu’’ Yüksek lisans Tesi,Dokuz Eylül Üniversitesi Fen Bilimleri Enstitüsü Kimya Anabilim Dalı,İzmir, (2012)

- Esra O , ‘’ Bebek Bezlerinin Performansını Etkileyen Özelliklerin Araştırılması ve Performans Özelliklerinin Karşılaştırılması ‘’ Pamukkale Üniversitesi Fen bilimleri Enstitüsü Tekstil Mühendisliği Anabilim Dalı Yüksek Lisans Tezi, (2018)

- Bilgici,Z, ‘’Bebek Bezindeki Polimerler Sıvıyı Nasıl Emer? ‘’ (16.12.2016) http://bilimgenc.tubitak.gov.tr/makale/bebek-bezindeki-polimerler-siviyi-nasil-emer,2016

- Bartkowiak,G, Frydrych, I , ‘’ Superabsorbents and their madical applications’’ , Bartels, V.T. (Ed), Handbook of Medical Textiles,Cambridge:Woodhead Publishing Limited, 505-546, (2011)

- Bulleri, B, ‘’ The Vortex Effect: liquid holding properties for fluffless and thinner diapers’’ , Insight 2014 Conference, Indianaoplis, (2014)

- Lee, S , ‘’Super Absorbent Polymer Market:Market Size and Market Trends Till 2020 ‘’, (2016) https://www.linkedin.com/pulse/super-polymer-market-size-trends-till-2020-smith-lee, (2015)

- Satellite Science and Tecnology Co., Ltd, 2018

- edana.org

Leave A Comment